There’s nothing lightweight about the safety of lightweighting.

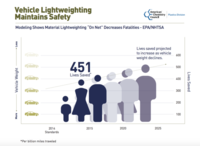

And although lightweighting is shown by the federal government’s own studies to be lifesaving (the EPA estimates that reducing vehicle weight can save approximately 451 lives per billion miles traveled), the current political climate is espousing that the “relatively cost-effective technology option of vehicle lightweighting…will increase on-road fatalities.”

The lightweighting materials industry strongly disagrees with the conclusions made in the recent CAFE-proposed rule.

The proposed rule contradicts NHTSA’s own studies from 2012 and 2017, which concluded that plastics and composites offer considerable weight savings while maintaining or improving safety. Evidence continues to support the view that heavier no longer means safer. Improved vehicle design has enabled lightweight materials and safety equipment to reduce mass and increase safety. In addition, lightweight plastic and polymer composites have improved design flexibility, enabling driver assistance and improving autonomous technology — two additional developments that can make our roads safer than ever before.

When a vehicle is constructed with lightweight materials, it leads to a reduction in fatalities per vehicle miles traveled (see chart). This is due in part to the properties of less stiff materials, such as plastic, which can prevent injury and save lives when used in the crumple zone. Plastic composite structures in the front end of a vehicle can lightweight without compromising safety. Fiber-reinforced polymer composite materials weigh around 50 percent less than steel, but are characterized by a higher absorption of crush energy per kilogram. On impact, carbon fibers can have four to five times higher energy absorption than steel or aluminum. This leads to the structure crushing in a relatively gradual, predictable way that absorbs much of the impact energy, keeping it away from the occupants and improving safety.

“We will always work to ensure the target number in the Safer Affordable Fuel-Efficient (SAFE) Vehicles Rule for Model Years 2021-2026 at the federal government level, is not based on incorrect assumptions regarding the safety of lightweight vehicles. We intend to continue highlighting the importance of automotive plastics and composites for lightweighting and safety innovations, enabling autonomous and electric vehicles, creating jobs, and establishing the U.S. as the global leader in advanced automotive manufacturing technologies. At the same time, the team will continue working with EPA and DOT leadership to illustrate the essential role of polymers for improved safety, autonomous driving, enhanced fuel economy and reduced GHG emissions,” according to Gina Oliver, Senior Director, ACC Automotive Center,

For additional resources on the safety of lightweighting cars and for use in social media, please use the links below.

Resources:

- Brochure: Plastics in Automotive

- Fact Sheet: Vehicle Lightweighting Saves Lives

- House Appropriations Bill: Departments of Transportation, and Housing and Urban Development, and Related Agencies, Appropriations Bill 2018

- Senate Appropriations Bill: 1655

- New Website: AutomotivePlastics.com

- More Sharable Infographic, Brochure, YouTube video links, and White-Paper available here

- Website: Institute for Advanced Composites Manufacturing Innovation (IACMI)

- Website: S. DOE’s Vehicle Technologies Office